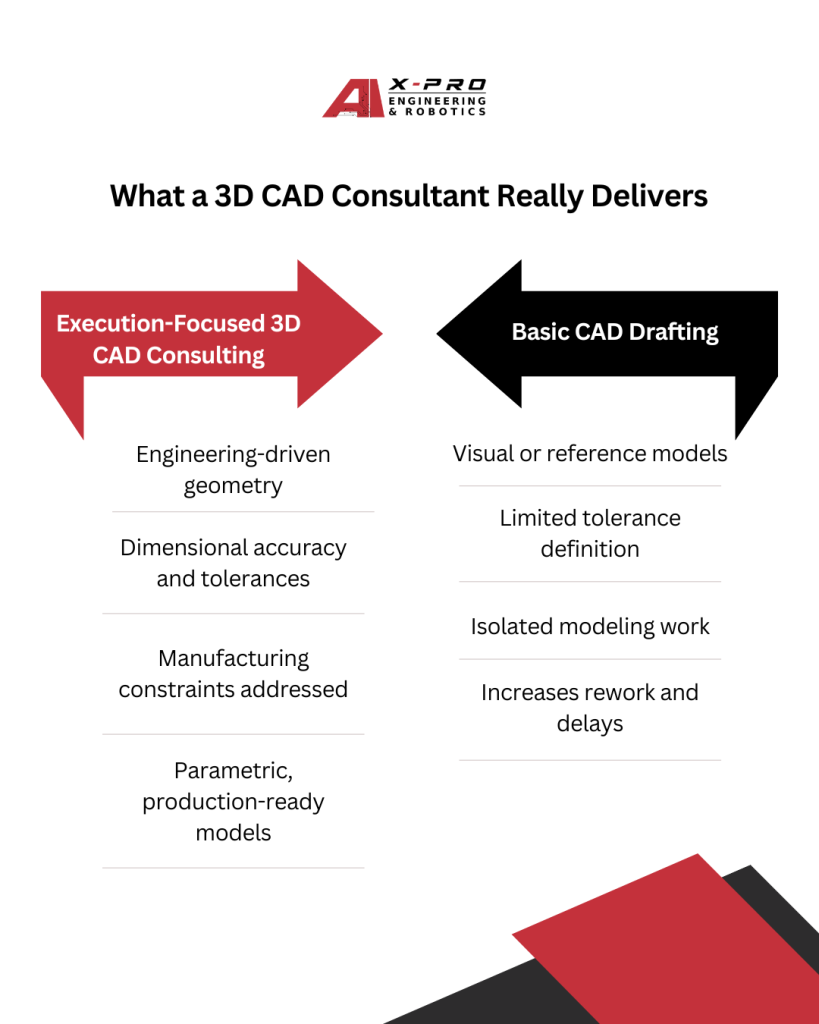

Up to 70 percent of rework in engineering and construction stems from design-induced errors, costing teams time and money they cannot afford. Most teams no longer hire a 3D CAD consultant to produce visually accurate models alone. Decision-makers expect CAD services to function as a reliable engineering input that supports manufacturing, reduces risk, and holds up under real production conditions. As products become more complex and timelines tighten, CAD must move beyond appearance and directly support execution.

However, many CAD engagements still focus on surface-level modeling.

These models may look correct on screen, yet they often ignore manufacturing constraints, tolerance requirements, and downstream engineering realities.

When teams treat CAD as a finished deliverable instead of a production tool, ambiguity enters the process. That ambiguity forces manufacturing teams to interpret intent, adjust designs on the shop floor, and absorb avoidable risk.

In contrast, execution-focused CAD consulting treats every model as part of a larger engineering system. Geometry, features, and assemblies exist to support fabrication, tooling, and assembly, not just visualization. When a 3D CAD consultant works with execution in mind, CAD data becomes a controlled, dependable asset that enables predictable outcomes rather than rework and delay.

This distinction marks the difference between CAD that looks correct and CAD that performs correctly.

What a 3D CAD Consultant Actually Does

A 3D CAD consultant does far more than create digital drawings or deliver 3D modeling outputs. In modern product development and manufacturing environments, decision-makers rely on CAD consultants to translate requirements into accurate, controlled engineering data that teams can use with confidence across the entire production process.

A professional 3D CAD consultant treats CAD as an engineering responsibility, not a drafting task. That role requires ownership of how geometry, dimensions, and assemblies behave once they leave the screen and enter real-world workflows. Every modeling decision affects tolerance stackups, material behavior, machining strategy, and assembly feasibility. That approach aligns CAD decisions with mechanical engineering requirements from the start.

Instead of working in isolation, an effective CAD consultant operates at the intersection of multiple disciplines. The work must align design intent with engineering constraints while remaining practical for manufacturing teams to execute without interpretation.

In practice, this means a 3D CAD consultant is responsible for:

- Creating models that reflect functional and mechanical requirements, not just visual intent

- Accounting for manufacturing constraints such as tolerances, tooling access, and material limitations

- Anticipating downstream impacts on machining, fabrication, and assembly

- Coordinating closely with engineers, product teams, and manufacturing stakeholders to maintain alignment

- Delivering CAD data that supports production planning, not just design approval

When CAD consulting focuses only on drafting, problems surface late and expensively. When it focuses on execution, CAD becomes a stabilizing force that reduces uncertainty and keeps projects moving forward.

Understanding this distinction shifts the conversation from what a CAD consultant produces to the value that consultant delivers.

Why Engineering Execution Matters More Than CAD Models

CAD models only create value when teams can use them directly in engineering and manufacturing workflows. When CAD work stops at visual correctness, problems surface late, where fixes cost the most. Poor execution turns CAD into a source of ambiguity instead of a control mechanism.

In production environments, ambiguity drives rework. Missing tolerances, unclear interfaces, and unvalidated assumptions force manufacturing teams to make decisions they should not have to make. Every interpretation introduces risk. That risk shows up as scrapped parts, machining adjustments, schedule delays, and cost overruns.

Execution-focused CAD changes that dynamic. Instead of asking production teams to “figure it out,” well-executed CAD defines intent precisely and removes guesswork. Geometry reflects how parts will be machined, assembled, and inspected. Dimensions exist to control outcomes, not just describe shape.

Every CAD decision carries a downstream consequence. Feature placement affects tool access. Tolerances influence scrap rates. Assembly references determine alignment and repeatability. When CAD accounts for these realities early, engineering teams stabilize production instead of reacting to problems after release.

The difference becomes clear when CAD supports execution rather than appearance. The table below highlights how execution-focused CAD directly impacts manufacturing outcomes.

CAD Execution vs Production Impact

This comparison shows how CAD execution quality directly influences manufacturing efficiency, cost, and production risk.

| CAD Approach | What Happens in Production | Business Impact |

|---|---|---|

| Visually correct models without manufacturing context | Shop floor interprets intent | Rework and inconsistent results |

| Missing or generic tolerances | Machining adjustments during production | Scrap, delays, higher cost |

| Geometry not aligned with tooling constraints | Inefficient setups and tool changes | Longer cycle times |

| Assemblies without clear interfaces | Fit and alignment issues | Assembly delays |

| Execution-focused, production-ready CAD | Direct fabrication and assembly | Predictable outcomes |

When teams treat CAD as an execution discipline, manufacturing becomes more controlled and repeatable. Engineers spend less time clarifying issues. Production teams move faster with fewer interruptions. Costs stabilize because fewer problems escape into the shop.

This execution-first approach becomes even more critical when CAD must support real manufacturing environments, where tolerances, tooling, and material behavior define success. That reality brings manufacturing-focused CAD consulting into focus.

Manufacturing-Focused CAD Consulting vs Generic CAD Services

Not all CAD services support manufacturing. While many providers deliver visually accurate models, only a manufacturing-focused CAD consultant builds CAD data that production teams can use without reinterpretation. The difference lies in how closely CAD work reflects real manufacturing conditions.

Generic CAD services often stop at geometry. Models look complete, but they fail to account for how parts will be machined, formed, or assembled. As a result, manufacturing teams receive CAD files that describe shape but do not control outcomes. That gap creates friction between engineering and production.

Manufacturing-focused CAD consulting approaches modeling as part of the production system. Geometry, dimensions, and features exist to support tooling, process selection, and repeatability. CAD decisions anticipate how materials behave under load, how tools access features, and how tolerances stack across assemblies.

The contrast becomes clear when comparing how each approach handles critical execution factors:

Generic CAD Services Typically Deliver

- Visually correct models without production context

- Minimal or default tolerances

- Features that ignore tooling access or fixturing needs

- Limited consideration of material behavior during fabrication

- CAD files that require interpretation on the shop floor

Manufacturing-Focused CAD Consulting Delivers

- Production-aware geometry built for specific processes

- Controlled tolerances based on function and capability

- Features designed around tooling, setups, and inspection

- Material-aware modeling that reflects real manufacturing behavior

- CAD data that supports direct fabrication and assembly

Manufacturing teams reject incomplete CAD because it transfers risk downstream. When tolerances remain undefined or features conflict with tooling constraints, production must pause to clarify intent or adjust designs. Those interruptions cost time, increase scrap, and undermine schedule reliability.

A manufacturing-focused CAD consultant eliminates that uncertainty by aligning CAD decisions with how parts actually get made. This alignment moves CAD beyond concept validation and positions it as a practical tool for execution, bridging the gap between design intent and production reality.

That focus on manufacturability sets the stage for understanding how mechanical CAD decisions directly influence real-world production performance.

How Mechanical 3D CAD Consulting Supports Real-World Production

Mechanical CAD exists to solve physical problems, not theoretical ones. A mechanical 3D CAD consultant builds models that reflect how forces, materials, and manufacturing processes interact in real production environments. Every line, feature, and dimension must respect mechanical constraints that determine whether a part can be manufactured efficiently and perform as intended.

Mechanical constraints shape geometry from the start. Key factors include:

- Load paths that influence wall thickness and rib placement

- Assembly forces that define clearances and interface design

- Material properties that affect feature size, transitions, and tolerances

When CAD ignores these constraints, parts may pass visual review but fail during machining, molding, or assembly.

Execution-focused CAD also supports specific manufacturing processes by design:

- Tool access drives feature orientation in CNC mašinska obrada

- Draft angles and parting lines affect injection molding design and release

- Bend radii and cut paths influence fabrication speed and repeatability

Mechanical CAD that accounts for these realities allows production teams to move from file to fabrication without rework.

On the shop floor, the impact of mechanical CAD decisions becomes measurable. Well-structured models reduce setup time, minimize tool changes, and simplify inspection. Clear tolerances prevent unnecessary adjustments, while consistent reference geometry improves alignment during assembly. These efficiencies compound across production runs.

A mechanical 3D CAD consultant connects engineering detail directly to operational performance. Instead of optimizing models for appearance, the focus stays on manufacturability, reliability, and repeatability. When CAD supports real-world production at this level, it stops serving engineering alone and starts delivering faster throughput, lower scrap rates, and predictable manufacturing outcomes.

CAD Consulting for Product Development Requires More Than Design

Product development depends on decisions made long before production begins. A CAD consultant for product development influences those decisions by shaping how a product moves from concept to manufacturing without unnecessary risk. When CAD focuses only on design output, teams lose control over cost, timelines, and scalability.

Execution-focused CAD guides the entire product lifecycle. Early modeling choices affect material selection, manufacturing methods, tooling strategy, and assembly flow. Each decision either reduces uncertainty or pushes it downstream, where changes cost more and delays compound.

Effective CAD consulting helps teams manage risk and iteration. Controlled geometry allows faster revisions without breaking assemblies. Clear constraints prevent late-stage redesigns. Scalable CAD structures support transitions from prototype to low-volume production and eventually to higher-volume manufacturing. Without this discipline, teams struggle to adapt as requirements evolve.

Early CAD decisions also define cost and schedule outcomes. Tolerances influence scrap rates. Feature complexity affects tooling and cycle time. Assembly design determines labor requirements. When CAD addresses these factors upfront, product development stays predictable instead of reactive.

The table below illustrates how CAD involvement shapes product development outcomes at different stages.

CAD Impact Across the Product Development Lifecycle

This overview shows how CAD decisions at each stage directly influence cost, risk, and development timelines.

| Product Development Stage | CAD Consulting Focus | Impact on Cost and Timeline |

|---|---|---|

| Concept definition | Evaluate feasibility and constraints | Prevents unrealistic designs |

| Early engineering | Define geometry and tolerances | Reduces redesign risk |

| Prototyping | Support rapid iteration | Shortens development cycles |

| Pre-production | Prepare manufacturing-ready CAD | Avoids late-stage changes |

| Scaling | Maintain controlled, adaptable models | Supports efficient growth |

A CAD consultant for product development does more than support design reviews. The role ensures that CAD remains a decision-making tool that aligns engineering intent with business objectives. This alignment helps teams move confidently toward production while preserving flexibility.

Choosing the right CAD consulting partner becomes critical when product development demands execution discipline rather than visual design alone.

When to Hire a 3D CAD Consultant Instead of Expanding In-House

Building internal CAD capacity makes sense in some situations. However, many teams reach a point where expanding headcount introduces more risk than it removes. In these cases, hiring a 3D CAD consultant provides faster access to execution-ready expertise without the long-term commitments of internal growth.

Outsourcing CAD works best when teams need immediate capability, controlled execution, and predictable delivery. Instead of recruiting, training, and managing additional staff, organizations can focus on outcomes while the consultant owns execution responsibility.

Scenarios Where Outsourcing CAD Reduces Risk

Hiring a 3D CAD consultant becomes the stronger option when:

- Project timelines require rapid ramp-up without onboarding delays

- Workload fluctuates and does not justify permanent headcount

- Manufacturing constraints demand specialized execution experience

- Internal teams need support without disruption to core engineering roles

- Product development carries high risk from late-stage changes

In these situations, outsourcing shifts execution risk away from internal teams and toward a partner structured to manage it.

From a cost and flexibility standpoint, consulting also delivers clear advantages. Teams avoid fixed salary overhead, benefit from scalable resources, and pay for execution rather than availability. This model allows organizations to increase or decrease CAD capacity as projects evolve.

Most importantly, a 3D CAD consultant does not function as a temporary replacement for internal staff. The role centers on execution ownership. The consultant assumes responsibility for delivering accurate, production-ready CAD that aligns with engineering and manufacturing requirements. Internal teams retain control over strategy and direction, while execution stays disciplined and accountable.

Understanding when to outsource CAD clarifies what to look for in a consulting partner and prepares teams to evaluate providers based on execution capability rather than staffing volume.

What to Look for in Professional 3D CAD Consulting Services

Not all 3D CAD consulting services deliver the same level of execution. While many providers can produce clean models, fewer operate with the process discipline required to support real manufacturing and product development. Evaluating CAD consultants based on execution capability rather than visual output helps teams reduce risk and avoid costly downstream issues.

Production Readiness Comes Before Visual Quality

Professional CAD consulting prioritizes how models perform in manufacturing environments. Visual clarity matters, but production readiness matters more. CAD must communicate intent precisely and support fabrication, assembly, and inspection without interpretation.

Execution-ready CAD typically demonstrates:

- Clearly defined tolerances tied to function

- Geometry aligned with manufacturing processes

- Assemblies structured for repeatable build sequences

- Consistent reference features for inspection and alignment

Aesthetic polish without these fundamentals creates false confidence and shifts risk to production teams.

Process Discipline Separates Consultants From Drafting Vendors

If you want to evaluate fit quickly, review how the process works before you compare providers. Strong CAD execution relies on repeatable processes. Professional consulting services follow structured workflows that control revisions, validate requirements, and maintain data integrity across handoffs. Without process discipline, even experienced modelers introduce inconsistency and rework.

Key indicators of disciplined CAD consulting include:

- Requirements validation before modeling begins

- Systematic revision and version control

- Clear documentation of assumptions and constraints

- Delivery formats aligned with downstream workflows

These practices ensure that CAD data remains reliable as projects evolve.

Execution Ownership Defines True CAD Consulting Value

The most important differentiator in professional CAD consulting lies in ownership. Effective consultants take responsibility for how CAD performs beyond design review. They align closely with engineering and manufacturing stakeholders to ensure models support real execution.

When CAD consulting services emphasize execution ownership, CAD becomes a dependable asset rather than a risk factor. That focus on reliability and accountability naturally leads teams to partners who treat CAD as an engineering discipline, not a visual task.

This execution-first perspective sets the stage for understanding how X-PRO CAD approaches 3D CAD consulting in practice.

How X-PRO CAD Approaches 3D CAD Consulting

X-PRO CAD approaches 3D CAD consulting as an execution discipline rather than a design service. The focus stays on delivering CAD data that performs reliably in engineering and manufacturing environments, where accuracy, clarity, and control determine outcomes.

The approach begins with execution-first thinking. CAD work starts from validated requirements and production realities, not assumptions. Geometry, tolerances, and assemblies exist to support fabrication, assembly, and inspection, ensuring that CAD data remains usable beyond design review.

Manufacturing awareness shapes every stage of modeling. X-PRO CAD accounts for tooling constraints, material behavior, and process limitations early, when changes remain efficient and low risk. This prevents late-stage redesigns and reduces friction between engineering and production teams.

Integration across engineering and production further strengthens execution. CAD work aligns with mechanical engineering decisions, prototyping requirements, and manufacturing workflows. This coordination reduces handoffs, limits interpretation, and maintains consistency from concept through production.

Global delivery enables scalability without sacrificing precision. Distributed teams operate under controlled standards, defined processes, and quality checks that ensure accuracy and repeatability across projects. Clients gain flexibility and cost efficiency while maintaining confidence in execution quality.

The table below summarizes how this approach differs from typical CAD consulting models.

X-PRO CAD Consulting Approach vs Typical CAD Services

| Area of Focus | X-PRO CAD Approach | Typical CAD Services |

|---|---|---|

| Core philosophy | Execution-first engineering | Model delivery |

| Manufacturing awareness | Built in from the start | Considered late or omitted |

| Engineering integration | Closely aligned | Often siloed |

| Production support | CAD supports fabrication and assembly | CAD requires interpretation |

| Delivery model | Global teams with precision control | Resource-based outsourcing |

By treating CAD as a controlled engineering input rather than a standalone deliverable, X-PRO CAD helps teams reduce risk, improve predictability, and move confidently toward production. This execution-focused approach naturally leads to clearer outcomes and more reliable manufacturing results, setting the foundation for the article’s conclusion.

Final Thoughts: Why the Right 3D CAD Consultant Shapes Real Outcomes

CAD does not create value through visuals alone. It drives outcomes when teams use it as a controlled engineering input that supports manufacturing, reduces uncertainty, and holds up under real production conditions. When organizations treat CAD as a deliverable instead of an execution discipline, risk accumulates quietly and surfaces late, where corrections cost the most.

The right 3D CAD consultant focuses on execution first. That focus ensures geometry reflects mechanical constraints, tolerances support function, and CAD data moves cleanly into fabrication and assembly. By aligning design intent with manufacturing reality, execution-driven CAD reduces rework, stabilizes timelines, and improves predictability across the product lifecycle.

At X-PRO CAD, CAD consulting centers on precision, manufacturability, and coordination between engineering and production. Our role is to help teams translate requirements into production-ready CAD that performs reliably beyond design review. Whether you are developing a new product, preparing for manufacturing, or resolving execution challenges, the objective remains the same: deliver CAD data that supports real-world results.

If you would like to discuss a project or evaluate how execution-focused CAD can reduce risk in your workflow, contact X-PRO CAD at project.inquiries@x-professionals.com or call (571) 583-3710.

Najčešća pitanja

What does a 3D CAD consultant do beyond creating models?

A 3D CAD consultant translates requirements into controlled engineering data that supports manufacturing and assembly. The role includes managing tolerances, accounting for mechanical and manufacturing constraints, and ensuring CAD data performs reliably in downstream workflows.

How does execution-focused CAD reduce manufacturing risk?

Execution-focused CAD removes ambiguity before production begins. Clear geometry, defined tolerances, and manufacturing-aware features prevent interpretation on the shop floor, which reduces rework, delays, and unexpected cost overruns.

Is manufacturing-focused CAD consulting only relevant for large production runs?

No. Manufacturing-focused CAD matters at every stage, including prototyping and low-volume production. Early execution discipline helps teams validate feasibility, control iteration, and scale efficiently without redesigning models later.

When should a company hire a CAD consultant instead of expanding an internal team?

Hiring a consultant makes sense when timelines require fast ramp-up, workloads fluctuate, or projects demand specialized execution expertise. Consulting allows teams to maintain flexibility while transferring execution responsibility to a partner.

What should companies look for in professional 3D CAD consulting services?

Teams should prioritize production readiness, process discipline, and execution ownership over visual quality alone. Strong consulting services validate requirements, manage revisions systematically, and deliver CAD data that supports real manufacturing outcomes.

Скорашњи коментари