In a survey of over 1,000 manufacturing organizations, 67 percent of respondents reported that using 3D CAD software enabled them to design with fewer errors, directly contributing to more accurate and reliable product development outcomes.

3D CAD modeling services provide the technical foundation for turning product requirements into accurate, manufacturing-ready digital models. At a professional level, CAD modeling is not about visual styling or conceptual design. It is about precision, dimensional control, and engineering execution that directly supports fabrication, assembly, and production.

High-quality 3D CAD modeling services ensure that geometry, tolerances, and features are defined with manufacturing constraints in mind from the start. When teams create models without this discipline, they trigger predictable rework, delays, and unnecessary costs once designs reach production.

Effective cad modeling services reduce those risks by aligning design intent with real-world manufacturing processes.

This approach serves engineering teams, product companies, and manufacturers that require reliable, production-ready CAD data rather than presentation models. For many organizations, outsourcing professional 3D CAD modeling services provides faster turnaround, access to specialized expertise, and scalable capacity without the overhead and inefficiencies of maintaining large in-house CAD resources.

Accurate CAD models are not a creative asset. They are an execution requirement.

What Are 3D CAD Modeling Services?

3D CAD modeling services involve the creation of precise, digital three-dimensional representations of parts, assemblies, and products using computer-aided design software. These models define geometry, dimensions, tolerances, and relationships between components in a way that supports engineering validation and downstream manufacturing.

At their core, CAD modeling services convert functional requirements into structured, editable digital data that teams can analyze, modify, and use directly for production planning.

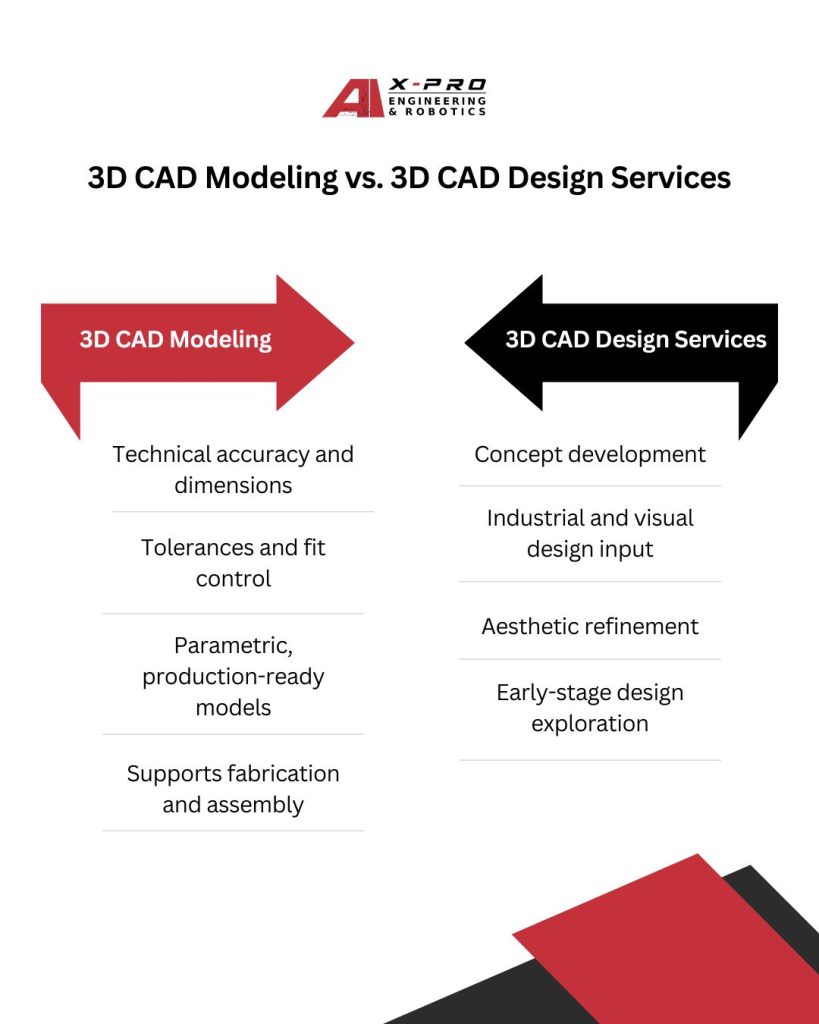

3D CAD Modeling vs. 3D CAD Design Services

While the terms are often used interchangeably, they serve different purposes:

- 3D CAD modeling focuses on technical accuracy, dimensional control, and manufacturability

- 3D CAD design services may include conceptual development, industrial design input, and visual refinement in addition to modeling

In engineering-driven projects, 3d cad modeling is the execution layer that ensures designs can be reliably produced, assembled, and scaled.

Where 3D CAD Modeling Fits in the Product Development Process

3D CAD modeling typically sits between initial product definition and physical production, supporting multiple stages of development:

- Converting requirements and sketches into precise digital geometry

- Enabling engineering analysis and fit checks before prototyping

- Supporting prototyping, tooling design, and manufacturing setup

- Allowing controlled revisions as requirements evolve

Well-structured models reduce uncertainty across the entire lifecycle by keeping design intent consistent from early development through production.

Key Elements of Professional CAD Modeling Services

Effective 3d cad modeling services include more than basic geometry creation. They account for:

- Parametric modeling, allowing controlled updates without rebuilding models

- Manufacturing tolerances appropriate to the selected production process

- Assemblies and relationships that reflect real-world fit and function

- Revision control, ensuring changes are tracked and communicated clearly

- Standard file formats, such as STEP, IGES, native CAD files, and 2D drawings, compatible with manufacturing and inspection workflows

When executed correctly, cad modeling services act as a reliable bridge between engineering intent and manufacturing reality.

Why Manufacturing-Ready CAD Models Matter

Manufacturing-ready CAD models directly affect cost, timelines, and production reliability. Models that look correct on screen but fail to account for real manufacturing constraints introduce risk at the most expensive stage of product development: when designs move from digital to physical.

When CAD models are not built with manufacturing in mind, issues surface late, where changes are slow and costly. This is one of the most common failure points in engineering-driven projects.

Risks of Non-Manufacturable CAD Models

CAD models that are not production-ready often lead to predictable and avoidable problems:

- Rework caused by incorrect dimensions, missing tolerances, or unfeasible features

- Cost overruns driven by repeated revisions, tooling changes, or scrap

- Production delays due to last-minute engineering fixes or supplier back-and-forth

These issues are rarely caused by manufacturing alone. They originate upstream, at the CAD modeling stage.

What Makes a CAD Model Manufacturing-Ready

Manufacturing-ready CAD modeling services account for how a part will actually be produced, assembled, and inspected. This requires more than clean geometry.

Key considerations include:

- Tolerances, defined appropriately for the manufacturing process and functional requirements

- Material behavior, including strength, thermal response, shrinkage, and surface finish limitations

- Process constraints, such as tool access, draft angles, minimum wall thickness, and achievable feature sizes

Whether the part is intended for CNC mašinska obrada, injection molding, casting, or additive manufacturing, these constraints must be embedded directly into the CAD model, not addressed later.

Manufacturing-Ready CAD vs. Non-Manufacturable CAD

The table below highlights the practical differences between CAD models created for visualization and those created for execution.

| Aspect | Non-Manufacturable CAD Model | Manufacturing-Ready CAD Model |

|---|---|---|

| Geometry | Visually correct but impractical | Aligned with real production limits |

| Tolerances | Missing or unrealistic | Defined for function and process |

| Material considerations | Generic or assumed | Matched to manufacturing method |

| Production feasibility | Requires redesign | Ready for fabrication and tooling |

| Cost impact | High risk of overruns | Predictable and controlled |

| Time to production | Extended due to rework | Shortened through upfront accuracy |

CAD Modeling as a Risk-Reduction Tool

In engineering-led organizations, CAD modeling is not a visual deliverable. It is a control mechanism. Accurate, manufacturing-ready CAD models reduce uncertainty by resolving constraints early, when changes are inexpensive and fast.

Well-executed cad modeling services act as a bridge between engineering intent and manufacturing reality, minimizing downstream surprises and protecting both timelines and budgets. This is why professional 3D CAD modeling services are evaluated not on how models look, but on how reliably they perform in production.

Our Professional 3D CAD Modeling Services

Our professional 3D CAD modeling services are built around execution, not presentation. Each service is structured to support accurate engineering decisions, controlled revisions, and smooth transition into prototyping and manufacturing. These capabilities are used by engineering teams and manufacturers that require dependable CAD data rather than conceptual visuals.

Parametric 3D CAD Modeling

Parametric modeling enables structured, flexible CAD models that can be efficiently updated as requirements change. This approach is critical for iterative development and long-term product scalability.

Key capabilities include:

- Fully editable, feature-based models

- Controlled dimensions and relationships between features

- Efficient design iteration without rebuilding geometry

- Scalable models that support future product variations

Parametric 3D CAD modeling reduces rework by allowing changes to propagate predictably throughout the model.

Mechanical & Engineering CAD Modeling Services

Engineering CAD modeling services focus on functional performance, structural integrity, and real-world operating conditions. These models are developed to support analysis, validation, and production planning.

This includes:

- Load-bearing and structural components

- Multi-part assemblies with defined constraints and fits

- Functional modeling aligned with mechanical requirements

- CAD data suitable for engineering review and validation

Mechanical CAD modeling prioritizes reliability and performance over visual refinement.

CAD Modeling for Manufacturing Processes

Manufacturing-specific CAD modeling ensures that parts are designed within the constraints of the intended production method. Geometry, tolerances, and features are tailored to how the part will be made.

Supported processes include:

- CNC machining, with tool access and machining limits considered

- Injection molding, including draft, wall thickness, and parting logic

- Sheet metal design, accounting for bends, reliefs, and flat patterns

- Additive manufacturing, optimized for print orientation and material behavior

This approach reduces downstream modifications and accelerates the move from design to production.

CAD Conversion & Redesign

Many projects begin with incomplete, outdated, or non-manufacturable CAD data. CAD conversion and redesign services bring those files up to production-ready standards.

These services include:

- Conversion of 2D drawings into accurate 3D CAD models

- Cleanup and restructuring of legacy CAD files

- Redesign to address manufacturability and production constraints

- Updates to support new materials or manufacturing processes

By combining conversion with design-for-manufacturing updates, 3D CAD design services become a practical tool for extending the life and value of existing designs.

Industries We Support With CAD Modeling Services

Our CAD modeling services support a wide range of engineering-driven industries where accuracy, manufacturability, and predictable execution are critical. Rather than applying generic modeling approaches, CAD data is developed with industry-specific constraints, standards, and production realities in mind.

Manufacturing

Manufacturing-focused CAD modeling services are built to support production efficiency and repeatability. Models account for tooling constraints, tolerances, and material behavior to ensure smooth transition from design to fabrication. This is especially important for parts and assemblies intended for CNC machining, molding, forming, or hybrid manufacturing workflows.

Industrial Equipment

Industrial equipment projects require durable, functional CAD models that reflect real operating conditions. CAD modeling in this space supports assemblies, moving components, and structural elements where fit, load, and reliability are critical. Models are developed to support long-term use, maintenance, and scalability rather than one-off prototypes.

Medical Devices

CAD modeling for medical and regulated products emphasizes precision, documentation, and consistency. Models are created to support tight tolerances, controlled revisions, and downstream validation processes. While regulatory requirements vary by application, CAD data must be reliable, traceable, and suitable for manufacturing environments where quality control is non-negotiable.

Consumer Hardware

Consumer hardware projects often combine functional requirements with cost and production constraints. CAD modeling services in this category focus on manufacturability at scale, part consolidation, and efficient assembly. Models are structured to support rapid iteration while remaining aligned with volume manufacturing processes.

Automotive and Aerospace Applications

CAD modeling for automotive and aerospace-related projects focuses on accuracy, structural integrity, and compatibility with established engineering workflows. Models are developed with attention to tolerances, material selection, and process limitations, without assuming specialized certifications or niche production capabilities.

By aligning CAD modeling services with the practical demands of each industry, engineering teams and manufacturers gain CAD data that supports real-world execution rather than abstract design intent.

Our CAD Modeling Process (Execution-Focused)

Our CAD modeling process is designed to minimize risk, control revisions, and produce reliable, manufacturing-ready CAD data. Each step is structured to eliminate ambiguity early and prevent costly changes later in the product lifecycle. The focus is on predictable execution, not creative interpretation.

Step-by-Step CAD Modeling Workflow

| Step | Process Stage | What Happens | Why It Matters |

|---|---|---|---|

| 1 | Requirements & Constraints Review | Functional requirements, materials, tolerances, and manufacturing constraints are reviewed and clarified upfront. | Prevents incorrect assumptions and downstream redesign. |

| 2 | Engineering-First Modeling | CAD models are built using parametric, feature-based methods aligned with engineering intent. | Ensures dimensional control and structured updates. |

| 3 | Manufacturability Validation | Geometry is evaluated against the intended manufacturing process and material behavior. | Reduces production risk and tooling issues. |

| 4 | Iteration & Revision Control | Changes are implemented in a controlled manner with clear revision tracking. | Maintains design integrity and avoids version confusion. |

| 5 | Final Delivery | Production-ready CAD files and supporting documentation are delivered. | Enables immediate use for prototyping, tooling, or manufacturing. |

Process Principles That Drive Reliability

This process follows a set of non-negotiable principles:

- Teams validate requirements before modeling begins.

- Engineers address manufacturing constraints early, not after design completion.

- Teams manage revisions systematically rather than informally.

- Teams deliver final CAD data in formats suitable for production workflows.

By treating CAD modeling as an execution discipline rather than a design exercise, this process provides engineering teams and manufacturers with CAD data they can rely on throughout development and production.

Why Companies Outsource 3D CAD Modeling Services

Many engineering-driven organizations choose to outsource 3D CAD modeling services not to reduce quality, but to improve efficiency, control costs, and accelerate execution. For decision-makers responsible for timelines, budgets, and production outcomes, outsourcing provides practical advantages that are difficult to achieve with fully in-house teams.

Cost Efficiency Compared to In-House Hiring

Maintaining internal CAD resources involves fixed costs that extend beyond salaries. Software licenses, training, workload fluctuations, and management overhead all contribute to higher long-term expense. Outsourcing CAD modeling services converts those fixed costs into predictable, project-based investment while maintaining access to experienced engineering talent.

Faster Turnaround Without Compromising Accuracy

Outsourced CAD teams handle defined scopes efficiently. With established workflows and dedicated modeling resources, professional 3D CAD modeling services often deliver faster turnaround than in-house teams balancing multiple internal priorities. This speed is especially valuable during early development, redesign cycles, or pre-production phases where time directly affects cost.

Access to Specialized Engineering Expertise

Engineering CAD modeling services require more than software proficiency. They demand understanding of tolerances, materials, and manufacturing processes. Outsourcing provides access to specialists who work across multiple industries and production methods, allowing organizations to apply the right expertise without long-term hiring commitments.

Scalable Capacity Without Operational Overhead

Product development workloads fluctuate. Outsourcing allows teams to scale CAD modeling capacity up or down based on project needs without increasing headcount or internal complexity. This flexibility enables better resource planning and reduces bottlenecks during peak development periods.

For engineering managers, product leaders, and operations teams, outsourcing CAD modeling services is not a shortcut. It is a strategic decision to improve execution reliability while maintaining cost and schedule control.

What to Look for in a 3D CAD Modeling Services Partner

Selecting a 3D CAD modeling services partner is an execution decision, not a creative one. The quality of the CAD data directly affects manufacturability, cost, and production timelines. Evaluating partners against clear, engineering-focused criteria helps avoid downstream risk and misalignment.

Key factors to assess include:

- Engineering competence, not just software proficiency

A capable partner understands mechanical principles, tolerances, and functional requirements, not only how to operate CAD software. CAD models should reflect engineering intent, not generic geometry. - Manufacturing awareness

CAD modeling services must account for real production constraints such as tooling access, material behavior, and process limitations. Partners should demonstrate experience with manufacturing methods relevant to your project. - Revision discipline and change control

Reliable partners manage revisions systematically, with clear versioning and traceability. Uncontrolled changes introduce errors and confusion, especially as projects move closer to production. - Clear communication and accountability

Teams should document and communicate expectations, assumptions, and changes consistently. A professional CAD partner takes responsibility for accuracy, not just file delivery. - Ability to support downstream production

CAD data should be ready for prototyping, tooling, inspection, and manufacturing handoff. Partners that understand downstream workflows reduce friction and shorten the path to production.

A strong CAD modeling services partner does not simply deliver files. They provide engineering-ready data that supports confident decision-making and reliable execution throughout the product development process.

Final Thoughts: From CAD Models to Production-Ready Execution

Engineering teams do not create accurate, manufacturing-ready CAD models by accident. They are the result of deliberate engineering decisions, controlled workflows, and a clear understanding of how designs move from digital files into physical production. When teams treat CAD modeling as an execution discipline rather than a visual exercise, they reduce risk and achieve more predictable outcomes.

At X-PRO CAD, we support that process from the earliest modeling stages through production preparation. Our work spans 3D CAD modeling, mechanical engineering, prototyping, and manufacturing support, allowing teams to move forward with confidence and control. Whether you are validating a design, preparing for manufacturing, or addressing production constraints, our role is to ensure your CAD data supports real-world execution.

If you would like to discuss a project or ask questions, contact us at project.inquiries@x-professionals.com or call (571) 583-3710. We are available to help evaluate your requirements and determine the most practical path from CAD modeling to production-ready results.

Najčešća pitanja

Is 3D CAD modeling the same as 3D CAD design services?

No. 3D CAD modeling focuses on technical accuracy, dimensions, tolerances, and manufacturability, while 3D CAD design services may include conceptual development, industrial design, and visual refinement in addition to modeling.

Are 3D CAD modeling services suitable for manufacturing, or just prototyping?

Professional 3D CAD modeling services support both prototyping and production. When engineers build models with manufacturing constraints in mind, teams can use them directly for tooling, fabrication, and production planning.

What file formats are typically delivered with CAD modeling services?

CAD modeling services commonly deliver production-ready formats such as STEP, IGES, native CAD files, and supporting 2D drawings, depending on manufacturing and client requirements.

Can CAD modeling services support revisions and design changes?

Yes. Parametric CAD modeling allows controlled updates and revisions without rebuilding models from scratch, helping teams adapt to changing requirements while maintaining accuracy.

When should a company outsource 3D CAD modeling services instead of handling them in-house?

Outsourcing is most effective when internal teams need additional capacity, faster turnaround, specialized expertise, or scalable support without the overhead of permanent staffing.

Скорашњи коментари