Prototyping is one of the most exciting stages in product development – it’s where your idea first comes to life in physical form. But it’s also a stage where mistakes can cost you more than just time and money. Rushing the process, overlooking critical details, or skipping essential tests can easily lead to failed launches or costly redesigns. Let’s walk through five of the most common prototyping mistakes and explore how to avoid them with smart, intentional planning.

One of the biggest pitfalls in prototyping is skipping iterations. It’s tempting to jump from an initial model straight to a “final” version, especially when deadlines or budgets are tight. But that first version is rarely perfect. Each iteration – whether it’s a rough concept model, a working prototype, or a near-final pre-production unit – serves a specific purpose. The early stages help refine shape, ergonomics, and user interaction, while later versions focus on function, performance, and manufacturability. Planning for at least three structured iterations ensures you’re catching problems early and building confidence at each level.

Another critical misstep is ignoring real-world use cases during testing. Too often, products are evaluated only in ideal lab conditions—smooth lighting, static surfaces, clean environments. In reality, your product might face heat, cold, drops, pressure, constant movement, or moisture. If you’re developing something that will be used outdoors, on the go, or in demanding environments, you need to prototype with those conditions in mind. Simulating real use—whether that’s testing under UV light, repeated mechanical stress, or even user misuse—helps expose flaws before they become customer complaints.

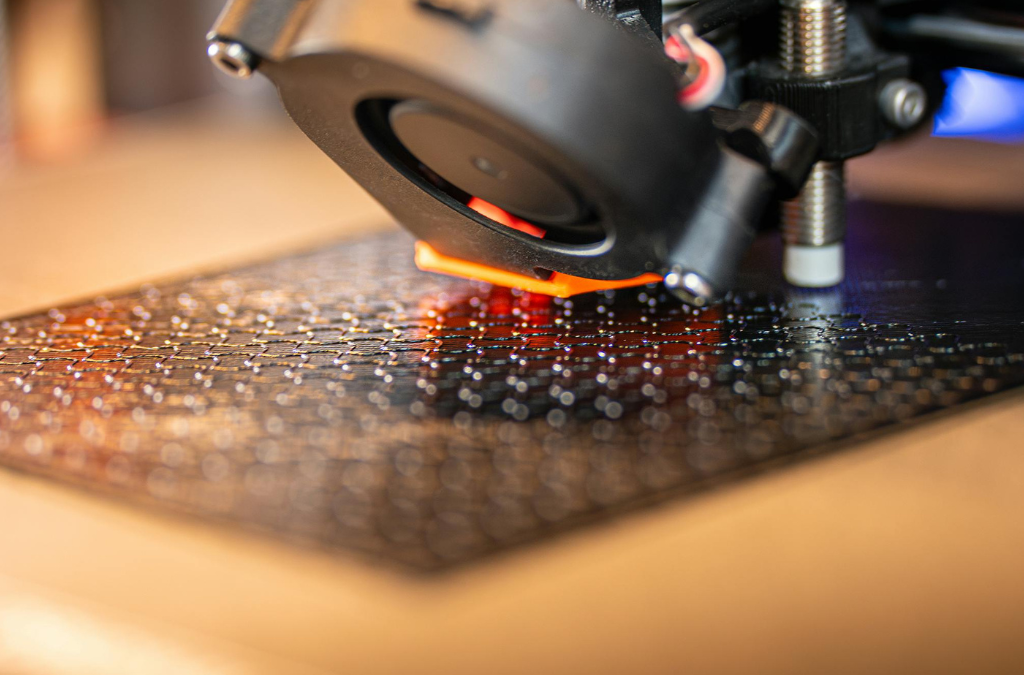

Using the wrong materials is another common problem. Many teams start prototyping with low-cost materials like PLA or basic resins, which may be easy to work with but don’t reflect the true properties of the final product. A prototype built with the wrong material may perform fine in early tests but fail entirely in production or real use. That’s why it’s essential to choose materials that mimic or match your end-use material. For example, if your product will eventually be injection-molded in ABS, prototyping in PLA could misrepresent flexibility, strength, or surface finish. It’s also wise to test alternative materials like polycarbonate, TPU, or even metal when performance or durability matters.

Then there’s overlooking tolerances and fit, a mistake that can delay entire projects. Just because parts look good in CAD doesn’t mean they’ll assemble well in real life. Tolerances – those small allowances for variation in part size – matter tremendously. Misaligned holes, loose fasteners, gaps between parts, or friction between moving pieces can all cause issues down the line. It’s critical to measure and verify everything. Use calipers, micrometers, or 3D scanners to check wall thicknesses, clearances, press fits, and other key dimensions. Tracking this data helps refine your CAD models and avoid surprises during tooling or mass production.

One client came to us with a medical device idea. We prototyped three iterations within two weeks, leading to crucial changes in button placement and grip. Their next investor pitch closed in a single meeting – thanks to a polished, test-proven prototype in hand.

Finally, a mistake that’s often overlooked: failing to prototype internal subsystems. A product isn’t just its exterior – it’s the full system of parts working together, including electronics, mechanical linkages, buttons, sensors, or displays. Teams sometimes test these subsystems separately or skip them altogether in early builds, assuming everything will “just fit” later. But real-world integration is rarely that simple. It’s important to prototype subassemblies early – such as wire routing, PCB layouts, switch travel, battery compartments, or mounting brackets. When all components are developed and tested in unison, you can spot potential conflicts and design around them before full-scale production begins.

Prototyping smart isn’t about having a perfect design from day one – it’s about learning fast, adapting quickly, and de-risking the development process through hands-on iteration. The best-performing products aren’t the ones that look perfect in CAD – they’re the ones that have been through multiple physical versions, tested under pressure, and refined in response to real-world feedback.

If you want to take your prototyping process to the next level, start by avoiding these five pitfalls. Iterate intentionally. Test realistically. Match your materials. Check your tolerances. And always think about the full system – not just the shell. With the right process, you’ll go to market faster, smarter, and with far less risk.

Ready to bring your idea to life? Book a free consultation and learn how our team can help you apply smart prototyping and manufacturing strategies to your next product. Let’s make it real – the right way.

Recent Comments