FORMING

Metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; The work piece is reshaped without adding or removing material, and its mass remains unchanged. CSMFG is an American owned company with experience in sheet metal forming since 2003. Our companies roll forming process begins by passing a long strip of coiled metal sheet through a series of incremental bends until a final cross-section profile is achieved. Besides, our team of roll forming experts can apply further improvements.

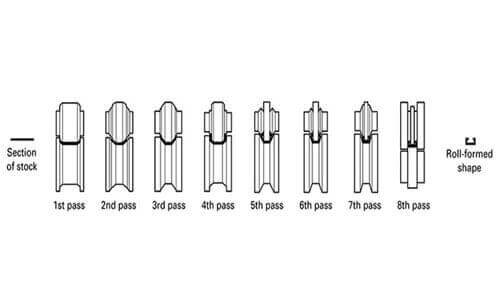

Roll forming

Roll forming is ideal for economically producing high volumes of close tolerance parts with a wide range of geometries. Our roll forming process makes metals into hardened states so that lower labor costs can be reached.

Advantages of roll forming

- Replace higher cost plastics and extruded parts

- Reduce waste, secondary operations and labor costs

- Compatible with both ferrous and non-ferrous metals

- Fabricate finished or painted parts

- Broad range of geometric opportunities

Roll forming capability

Roll forming machines are available that produce shapes of different sizes and material thicknesses using the same rolls. Variations in size are achieved by making the distances between the rolls variable by manual adjustment or computerized controls, allowing for rapid changeover. And, Tolerances can typically be held within ±0.015 inches (0.38 mm) for the width of the cross-sectional form, and ±0.060 inches (1.5 mm) for its depth.

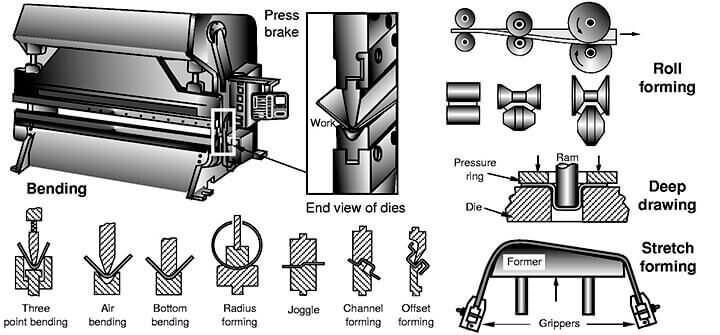

We use different kind of forming to achieve the most cost effective solution for our customer

Compressive forming

- Extrusion – where the material is pushed through an orifice

- Die forming – where the material is stamped by a press around or onto a die

- Forging – where the material is shaped by localized compressive forces

- Intending – where a tool is pressed into the work piece

Tensile forming

- Stretching – where a tensile load is applied along the longitudinal axis of the work piece

- Expanding – where the circumference of a hollow body is increased by tangential loading

- Recessing – where depressions and holes are formed through tensile loadinga

Combined Tensile and Compressive forming

- Pulling through a die, deep drawing, spinning, flange forming, upset bulging, roll forming

How Can X-Pro Help With My Project?

X-Pro helps clients with one-time and ongoing project needs. Our specialties include 3D modeling, 3D design, CAD drafting, 3D animation, engineering and 3D renderings, 3D industrial design, prototype design, 3D printing design, mechanical design, architectural design, structural design, 3D interior design, and CAD landscaping design services.

Our CAD designers and drafting contractors work with AutoCAD, SolidWorks, Autodesk Inventor, Maya, 3ds Max, CATIA and many other types of software. Submit your project description and work with a pre-qualified 3D artist, CAD designer, drafter, 3D modeler, 3D animation or engineer specialized for your project needs.

The Project Flow

1. Tell us about your project

Describe your project, estimate the number of hours needed, the duration, and software requirements.

2. Pre-qualified expert freelancer

One of our engineers will contact you to discuss your project and gather more details.

3. Deposit & work

Agreement will need to be signed and payment deposit made in order to begin a project.

FAQ for your new project

Why X-Pro?

We connect you with the best designers in the business, and we offer the most comprehensive set of services for inventors you’ll find anywhere. We take the guesswork out of online design services, and let you focus on what’s important.

How do private projects work?

Simple. Just send us a project brief and we will provide you with a design quote from a pre-qualified designer for your project.

Who can see my project?

Private projects are entirely confidential. Only you and the designer that you will be working with will see your project description, file attachments and submitted work.

Do I own the designs & IP?

Yes. Our legally binding terms of service assign the ownership of intellectual property (IP) from the designer to the service buyer for any paid designs.

Do you offer manufacturing services?

Yes we do! We offer a range of manufacturing services, including 3D printing, rapid manufacturing and conventional injection molding.

How is a design project different from hourly services?

Design projects are limited-term projects with a concrete budget, based on an upfront quote from the CAD designer. Hourly services are for ongoing work that generally have an open work scope.

Will designers sign a NDA?

We’ve got this covered. Our legally binding terms of service covers freelancer non-disclosure. Freelancers on X-Pro have agreed to and are bound by the terms of non-disclosure that are outlined in our terms of service.

Got a question? Get in touch

We’re here to help. Send us an email or get a personalized quote.

WE ARE HERE FOR YOU

24 Hours a day

7 days a week

365 days a year

FOLLOW US

JOIN OUR NEWSLETTER

*By subscribing you agree to receive SMS notifications from X-PRO CAD. Reply HELP for help, STOP to unsubscribe.