For engineers, product developers, and entrepreneurs, CNC machining is one of the most precise and versatile methods for bringing concepts to life. Whether you’re creating a prototype, small batch production, or high-precision components, CNC technology allows for repeatable, accurate, and high-quality results.

However, setting up a CNC shop requires significant investment, knowledge, and expertise. From machine selection to tooling, software, and process management, the path can be complex. This is where professional support can make a significant difference.

Understanding CNC Machining

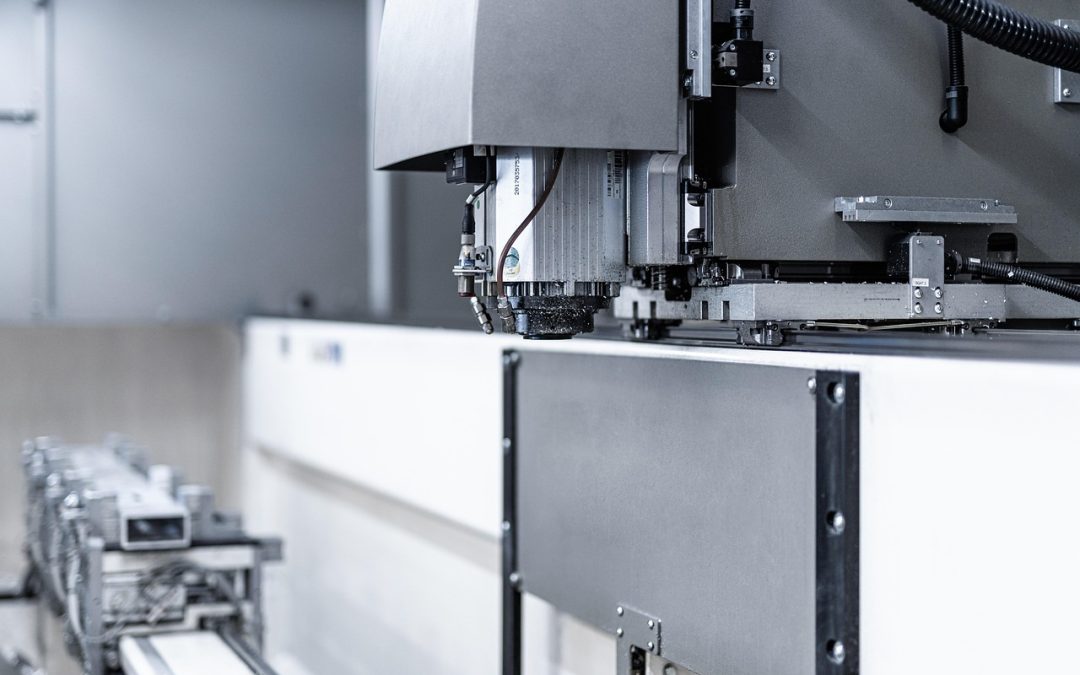

CNC, or Computer Numerical Control, is a method where pre-programmed software controls machine tools such as mills, lathes, and routers. Unlike manual machining, CNC provides automation, repeatability, and the ability to produce complex shapes with extremely tight tolerances.

This technology is widely used across industries—from automotive and aerospace to medical devices, consumer products, and even high-end prototypes—because of its precision, consistency, and flexibility.

Key CNC Capabilities

A comprehensive CNC setup typically includes several types of machines:

- CNC Milling: Uses rotary cutting tools to remove material from stationary workpieces. Perfect for 3D shapes and intricate features, milling machines range from entry-level 3-axis setups to advanced 5-axis centers capable of producing high-precision components.

- CNC Turning (Lathes): Spins the workpiece to create round parts like shafts, pins, and bushings. Modern lathes with live tooling allow for milling and drilling in a single setup, reducing time and increasing accuracy.

- CNC Routing: Primarily for softer materials such as plastics, wood, and composites. Routing is ideal for signage, furniture components, and consumer product parts.

Advanced shops may also include:

- Water Jet Cutters for thick metals, ceramics, or stone.

- Wire EDM Machines for precise cutting of hard metals.

- Laser Cutters for high-speed sheet metal and detailed cuts.

- Robotic Arms for automated loading, unloading, inspection, or welding.

Tooling, Fixtures, and Software

Precision tooling and fixtures are essential for reliable results. Collets, insert holders, anvils, and custom fixtures ensure parts are accurately held during machining. Effective tool management, including life tracking and replacement planning, keeps operations efficient.

Software is equally important. CAD software like SolidWorks or Inventor designs the components, while CAM programs generate the toolpaths for precise machining. Integrated software ensures consistency, reduces errors, and allows for complex part production.

Bringing CNC Capabilities Within Reach

Investing in a full CNC shop is a major commitment, but professional support can make these capabilities accessible without the overhead. By partnering with an experienced CNC service provider, you can:

- Turn sketches and CAD designs into high-quality prototypes.

- Produce small or medium-scale batches with precision.

- Access advanced machining capabilities without owning the machines.

- Benefit from tooling expertise, process optimization, and quality control.

This approach allows product developers and entrepreneurs to focus on design, strategy, and business growth, while experienced CNC teams handle execution, ensuring parts meet exact specifications efficiently.

Why Working with Professionals Makes a Difference

Precision machining isn’t just about having the right machines—it’s about experience, process, and attention to detail. Partnering with a skilled CNC team ensures:

- Faster turnaround times for prototypes and production runs.

- Optimized machining strategies to save time and material.

- Reliable quality control for every part.

- Expert guidance on materials, tolerances, and production feasibility.

By leveraging professional CNC services, businesses can realize their ideas faster, with confidence that every component meets the required standards.

Whether it’s a single prototype or a batch of complex components, professional CNC support makes it possible to focus on innovation while leaving the precision manufacturing to the experts.

Recent Comments