What is CNC Machining?

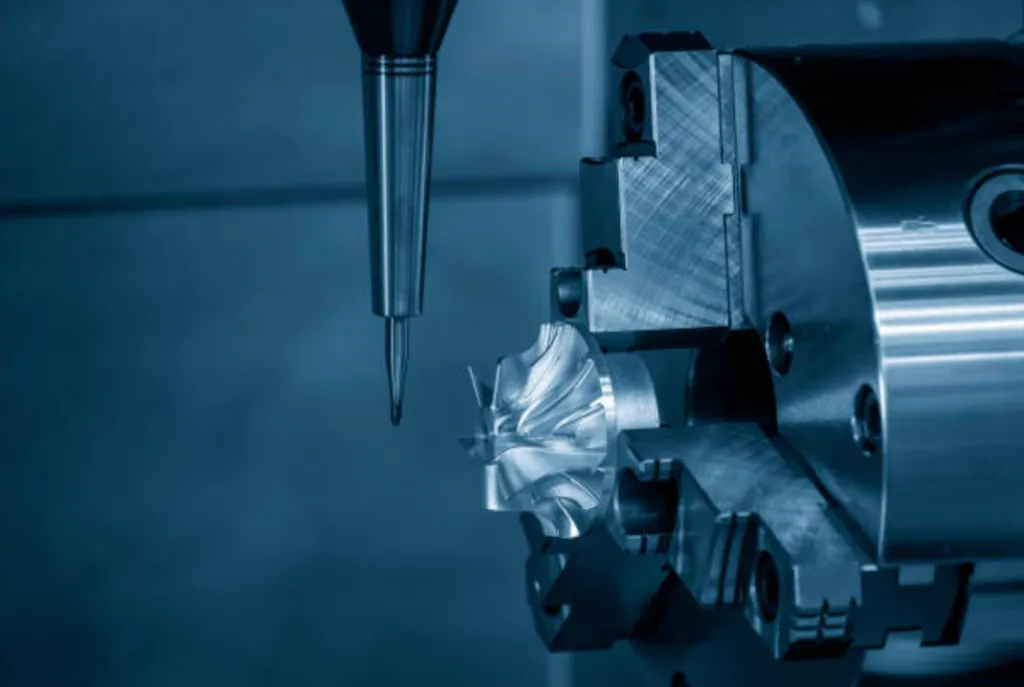

CNC Machining is a computerized manufacturing process whereby machine-driven cutting tools create parts through subtractive machining technology. CAM software is used to program toolpaths and to generate the G-code that controls CNC machines like mills, routers, lathes, and wire EDMs. What is so significant about this process? Due to the automated processes, there is little room for human error.

Consider an average Boeing 777 (made up of 3 million individual parts) that flies 3,500 hours a year over the course of a 30-year lifetime. That’s a lot of fuel and a great reliance on quality parts for the aircraft to withstand the harsh flight conditions and run that long.

Lightweight Metals

The lighter the aircraft, the more fuel-efficient the aircraft is, and therefore, more cost-efficient. For this reason, although considered strong, metals such as steel are not ideal for aircraft components. Strong and lightweight metal like titanium and aluminium alloys are ideal in the aerospace industry.

- Titanium is stronger and 45% lighter than steel. It also boasts excellent resistance to corrosion and have the ability to withstand extreme temperatures, making it a good choice for longevity and consistency of performance. A popular aerospace-grade titanium is Ti6Al4V, sometimes known as Grade 5 or TC4.

- Aluminium is suited for a wide range of aircraft components. Despite being only about half as strong as titanium, its greater weight-saving aspect makes it more cost-effective and a popular choice in the industry. A common grade of aluminium for aerospace is Al7075-T6.

But here’s the problem: these metals are often tough to machine manually. CNC machinery boasts compatibility with a wide range of materials and is heavily relied on to fabricate these metals.

High Performance Plastics

Although metal components boast more applications in an aircraft’s functional structures, many interior components such as wall panels, ventilation ducts, aircraft doors, bearings, and more are made from plastics – more specifically, high-performance plastics. They are lightweight, robust, and meet aerospace fire retardant regulations. These aerospace-grade plastics include PEEK and other high-performance polymers.

Similar to metals, CNC Machinery boasts compatibility with plastics.

-1024x560-1.jpg)

Model Complexity

Simply explained: the main difference between 3, 4 and 5-axis machining lies in the complexity of the movement. The more complex the movement, the more complex the geometry of the final machined part can be.

3 and 4-axis CNC machines offer a level of precision that is sufficient for many aircraft components; however, in instances where a greater complexity or precision is required, 5-axis milling machines are available. It allows parts to be machined, drilled, and maneuvered simultaneously along the X, Y, Z, and linear axes without the need to rearrange or refix the component.

Why is complexity valued in the aircraft industry? Producing a component with a partly hollowed out or complex shape can help shed unnecessary weight without compromising quality or performance.

High Precision Parts

High precision machining enables aircraft parts to be manufactured meticulously as specified and delivered on tight tolerances. As mentioned, with CNC machining, there is little room for human error. In an industry where part failure while being in the air is not an option, CNC machining is the solution.

Precision CNC machining is not just vital in the making of end-use aircraft components but also in aerospace R&D.

Rapid Prototyping

When thinking of rapid prototyping solutions, 3D printing often first comes to mind; however, many aren’t aware that CNC machining is an ideal one-off prototyping solution for the right projects. It’s fast, dimensionally accurate and perfect for making strong mechanical parts that need to be fully functional and have precise tolerances. In an R&D intensive industry, CNC machining is salient to efficiently and swiftly prototype new component designs, test them, and, if necessary, make changes.

0 Comments