Research shows that up to 95% of new products underperform or fail, often because early development stages like prototyping don’t align with real production and market needs. A large percentage of product failures do not originate from flawed concepts. They originate at the prototype stage.

When a prototype is built without proper engineering oversight, tolerance conflicts, material mismatches, and manufacturability gaps surface late. What should have been a validation milestone becomes the start of rework cycles, schedule slips, and cost overruns. By the time production begins, those early decisions are already embedded in tooling, supply chains, and budgets.

The problem is not access to equipment. The market is full of prototypes suppliers offering CNC machining, 3D printing, and short-run molding. The real risk lies in whether those suppliers are simply fabricating what they are given, or actively engineering for downstream production.

A true execution partner evaluates CAD data, questions assumptions, flags risks early, and designs prototypes with manufacturing constraints in mind. A transactional supplier manufactures to file and moves on.

Understanding that distinction is critical. The difference determines whether your prototype reduces risk or quietly multiplies it.

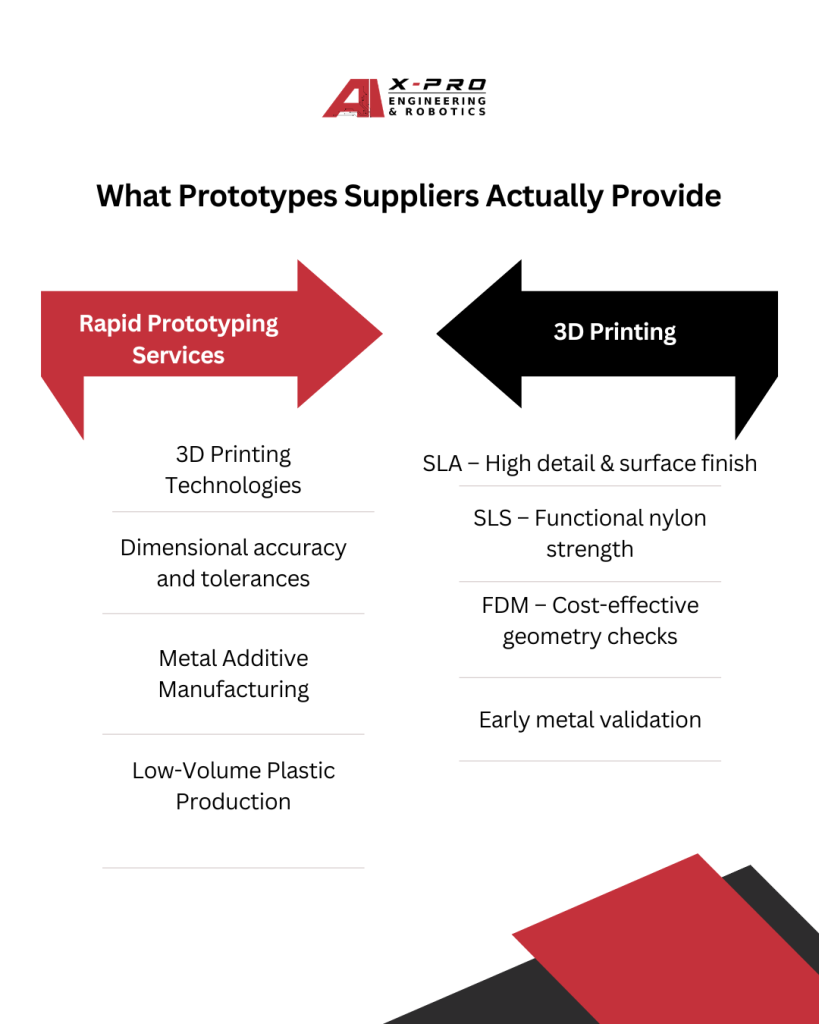

What Do Prototypes Suppliers Actually Provide?

Not all prototypes suppliers offer the same capabilities. Some operate as single-process shops focused on speed, while others provide multi-process support designed to validate both function and manufacturability.

Understanding what services are available helps you determine whether a supplier can support early validation only, or guide a product toward production readiness.

Below are the most common rapid prototyping capabilities.

Rapid Prototyping Services

Rapid prototyping focuses on producing early-stage physical parts quickly, typically for form, fit, and initial functional validation.

Most prototypes suppliers offer some combination of the following:

- 3D Printing Technologies

- SLA (Stereolithography): High surface quality and detail, suitable for visual models and fine-feature validation

- SLS (Selective Laser Sintering): Stronger nylon parts, better for functional testing

- FDM (Fused Deposition Modeling): Cost-effective for early-stage geometry checks and non-critical testing

- Metal Additive Manufacturing

- Suitable for complex internal geometries

- Used for lightweight structures or early metal validation

- Often applied in aerospace, medical, and performance-driven applications

- Low-Volume Plastic Production

- Bridge manufacturing before full tooling

- Short-run injection molding or urethane casting

- Useful for pilot batches, market testing, or regulatory samples

These services enable fast iteration. However, speed alone does not determine prototype quality. The real differentiator is whether the supplier evaluates design intent, material selection, and downstream manufacturing constraints before production begins.

CNC Machining for Functional Prototypes

While 3D printing is useful for early validation, CNC machining remains the standard for high-accuracy, functional prototypes. When a part must behave like the final production component, machining provides material integrity, dimensional precision, and realistic performance characteristics.

CNC machining is commonly used when:

- Mechanical loads must be tested

- Tight tolerances are critical

- Surface finish affects function

- The prototype must mirror production intent

Common Materials

Most prototypes suppliers machine functional parts from production-grade materials, including:

- Aluminum

- Lightweight and machinable

- Common in automotive, aerospace, and industrial components

- Suitable for structural and enclosure parts

- Steel

- Higher strength and durability

- Used for load-bearing or wear-resistant components

- Often selected for industrial validation

- Titanium

- High strength-to-weight ratio

- Corrosion-resistant

- Applied in aerospace and medical applications

Material choice directly impacts performance testing accuracy. A supplier should evaluate whether the selected material aligns with final production requirements.

Tight Tolerance Capability

Functional prototypes often require precise dimensional control. Reliable CNC-based prototypes suppliers must demonstrate:

- Interpretation of GD&T specifications

- Controlled machining strategies

- Measured verification and inspection reports

- Repeatability across multiple parts

If tolerances are loosely controlled at the prototype stage, production risks increase significantly.

Surface Finishing Considerations

Surface finish is not cosmetic in many applications. It can affect sealing, friction, wear, and assembly fit.

Common finishing processes include:

- Bead blasting

- Anodizing

- Powder coating

- Polishing or brushing

A competent supplier evaluates whether surface treatments are required for functional testing or only for appearance.

CNC machining for prototypes is not simply about cutting metal. It is about validating performance under realistic conditions. When executed correctly, it reduces uncertainty before production tooling begins.

Injection Molding for Prototype Tooling

When a product is moving beyond early validation and closer to production, injection molding becomes critical. At this stage, the goal is no longer just geometry confirmation. It is process validation, material behavior testing, and preparation for scalable manufacturing.

Prototypes suppliers that offer injection molding support typically provide:

Bridge Tooling

Bridge tooling is used when a product is nearing launch but full-scale production tooling is not yet justified.

It allows teams to:

- Produce limited batches before investing in hardened steel molds

- Validate design performance in real production materials

- Test market response before committing to high-volume manufacturing

- Reduce time-to-market while final tooling is being prepared

Bridge tooling balances cost control with production realism.

Short-Run Molds

Short-run molds are designed for low-volume production runs.

They are commonly used for:

- Pilot batches

- Regulatory submissions

- Investor demonstrations

- Controlled field testing

Compared to full production tooling, short-run molds:

- Require lower upfront investment

- Have shorter lead times

- Are suitable for design iterations before scale

However, they must still reflect real manufacturing constraints. Poorly engineered short-run molds often create misleading validation results.

Material Validation

Injection molding at the prototype stage enables proper material testing under realistic conditions.

This includes:

- Evaluating mechanical properties

- Assessing shrinkage and warping behavior

- Testing heat and chemical resistance

- Verifying cosmetic and surface quality

Material validation ensures that the transition from prototype to production does not introduce unexpected performance failures.

Multi-Process Suppliers vs Single-Process Shops

Not all prototypes suppliers operate at the same level of integration.

Some specialize in one process. Others provide a coordinated, multi-process capability that supports the full development cycle.

Below is a clear comparison:

| Evaluation Area | Single-Process Shop | Multi-Process Supplier |

|---|---|---|

| Service Scope | One manufacturing method | CNC, additive, molding, finishing |

| Engineering Oversight | Limited to fabrication | Broader manufacturability review |

| Process Transitions | Requires external vendors | Managed internally |

| Communication Complexity | Multiple handoffs | Centralized coordination |

| Risk of Misalignment | Higher | Lower |

| Production Readiness | Often disconnected | Designed with scale in mind |

Advantages of Integrated Providers

Working with a multi-process supplier provides measurable advantages:

- Reduced vendor coordination

- Faster iteration cycles

- Unified engineering review

- Better alignment between prototype and production intent

- Lower probability of tolerance and material conflicts

Reduced Coordination Complexity

Fragmented supplier networks introduce risk through:

- File version confusion

- Conflicting process assumptions

- Communication delays

- Unclear responsibility for errors

An integrated provider centralizes accountability and reduces friction between stages.

Lower Error Probability

Errors in prototyping often originate at process boundaries.

When machining, molding, finishing, and engineering are disconnected:

- Design assumptions are not cross-checked

- Manufacturing constraints are overlooked

- Problems are discovered late

Integrated execution reduces these failure points.

The problem is rarely access to machines. Modern fabrication technologies are widely available.

The real differentiator is execution discipline — the ability to align engineering, material selection, process capability, and production intent from the first prototype onward.

The Critical Difference: Prototype Vendor vs Engineering Partner

At a surface level, most prototypes suppliers appear similar. They offer machining, printing, molding, and competitive lead times. The difference becomes visible only when something goes wrong.

A prototype vendor focuses on fabrication. An engineering partner focuses on outcome.

Vendors Typically:

- Manufacture exactly what they receive

- Quote based on file input, not engineering intent

- Flag design issues late in the process

- Prioritize machine utilization and throughput

- Treat prototyping as a transactional service

This approach may deliver parts quickly, but it does not actively reduce production risk.

Engineering-Integrated Suppliers:

- Review CAD files for manufacturability before cutting material

- Identify tolerance stack-ups and geometric conflicts

- Recommend material substitutions when performance risks exist

- Align prototype decisions with future tooling constraints

- Evaluate how the part will transition to production

This model treats prototyping as a controlled engineering phase, not a fabrication task.

For companies developing real products, this distinction matters. A prototype should not simply represent a design. It should de-risk production.

That execution-focused approach is central to how X-PRO CAD operates — integrating CAD, mechanical engineering, prototyping, and manufacturing considerations under one coordinated framework.

Execution partner, reduced handoffs, fewer errors About the Company – X-PRO CAD

Common Risks When Choosing the Wrong Prototype Supplier

Choosing a prototype supplier based only on price or speed often shifts risk downstream. The prototype may look acceptable in isolation, but hidden engineering gaps surface during testing, pilot production, or full-scale manufacturing.

Below are common failure scenarios that result from weak execution oversight.

Tolerance Stack-Ups Ignored

When dimensional tolerances are not reviewed holistically:

- Individual parts may be within spec

- Assemblies may still fail

- Fitment issues appear during integration

- Performance becomes inconsistent

Tolerance stack-ups are rarely visible in isolated part fabrication. They must be engineered deliberately.

Incorrect Material Selection

Selecting a material based on availability rather than function can lead to:

- Premature wear or cracking

- Heat deformation

- Chemical incompatibility

- Misleading performance validation

A prototype built from the wrong material may pass visual inspection but fail under real operating conditions.

Surface Finish Unsuitable for End-Use

Surface finishing is not cosmetic in many applications.

Improper finish can cause:

- Sealing failures

- Increased friction

- Poor coating adhesion

- Corrosion risk

Ignoring finishing requirements during prototyping often leads to redesign before production.

Prototype Passes but Fails in Production

One of the most expensive mistakes occurs when:

- The prototype is validated

- Production tooling is commissioned

- Manufacturing constraints expose hidden design flaws

At this stage, changes affect tooling, supply chains, and schedules. Corrections become significantly more costly.

Rework Cycles That Double Costs

Repeated iteration due to incomplete engineering review can:

- Extend timelines by weeks or months

- Increase machining and material waste

- Delay market entry

- Reduce investor or stakeholder confidence

The financial impact compounds with each revision cycle.

Risk Comparison Table

| Risk Area | What Goes Wrong | Downstream Impact |

|---|---|---|

| Tolerance Control | Stack-ups not analyzed | Assembly failures and redesign |

| Material Selection | Functional mismatch | Performance failure in testing |

| Surface Finish | Incorrect treatment | Sealing, wear, or corrosion issues |

| Production Transition | Prototype not production-aligned | Tooling rework and launch delays |

| Iteration Control | Reactive corrections | Cost overruns and schedule slips |

Prototype errors are rarely isolated events. They create cascading consequences that affect tooling investment, supplier coordination, and time-to-market.

The cost of a disciplined engineering review at the prototype stage is minimal compared to correcting mistakes after production has begun.

Conclusion: The Right Prototype Supplier Reduces Risk Before Production Begins

Choosing between prototypes suppliers is not a purchasing decision. It is a risk management decision.

The prototype stage defines how a product behaves in production. Tolerances, materials, surface treatments, and process constraints either get validated early or become expensive corrections later. When suppliers operate purely as fabrication vendors, responsibility for downstream consequences remains fragmented. When engineering oversight is integrated from the beginning, risk is controlled before capital is committed to tooling and scale.

Modern manufacturing technology is widely accessible. CNC machines, additive systems, and molding capabilities are not the constraint. Execution discipline is.

Companies that move successfully from prototype to production work with partners who:

- Review CAD with manufacturability in mind

- Align prototype materials with production intent

- Evaluate tolerance interactions before assembly

- Plan transition to tooling from the first iteration

This approach reduces rework cycles, protects timelines, and improves confidence before scaling.

At X-PRO CAD, prototyping is integrated with CAD engineering, mechanical validation, and manufacturing planning under a single execution framework. We support product teams and manufacturers that require precision, coordinated delivery, and production readiness from the earliest stages of development. To discuss your prototype or production requirements, contact us at project.inquiries@x-professionals.com or call +1 (571) 583-3710. Additional information about our capabilities is available at www.x-procad.com.

Recent Comments