As modern industries shift towards more precise and efficient manufacturing, CAD (Computer-Aided Design) software has become a critical tool for streamlining production. In this blog, we’ll explore how CAD software helps designers and engineers optimize their workflows, reduce production costs, and enhance product quality.

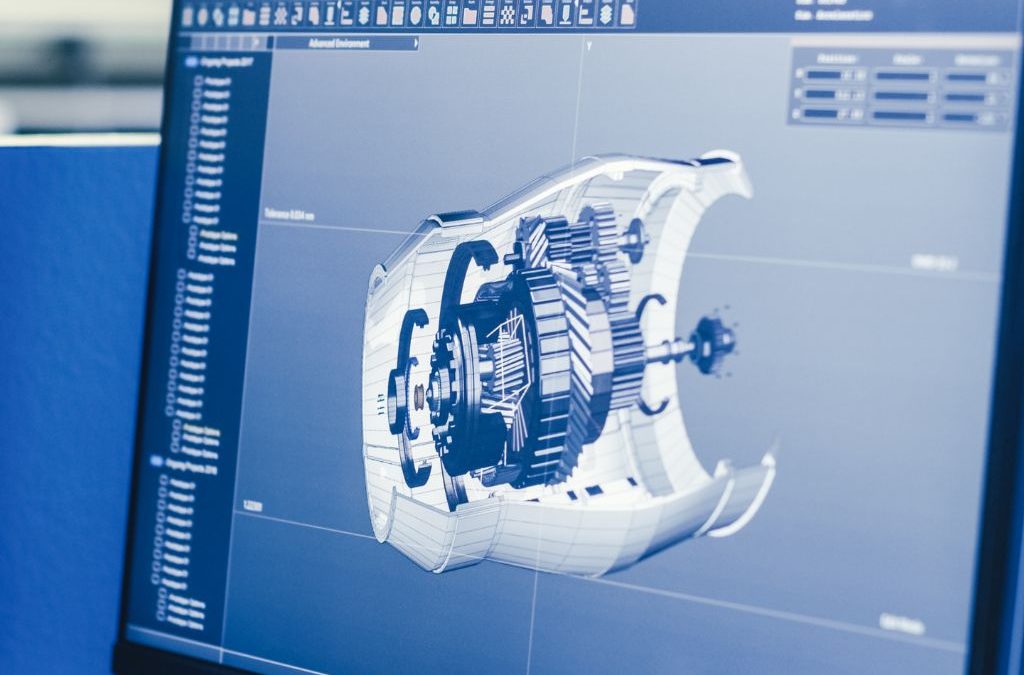

In the realm of product development, efficiency and precision are key factors that can make or break a project. This is where CAD software shines, transforming the way products are designed and manufactured. Unlike traditional drafting, CAD allows engineers to create detailed digital models that simulate real-world conditions. These models not only make it easier to visualize the final product, but they also enable teams to detect potential issues before they arise.

One of the greatest benefits of CAD is its ability to integrate with CAM (Computer-Aided Manufacturing) software, creating a seamless process from design to production. The design created in CAD can be directly converted into instructions for manufacturing machines, such as CNC machines, drastically reducing the time between concept and creation.

Moreover, CAD software helps with optimizing material usage, reducing waste, and ensuring that parts fit together perfectly, which is crucial in industries that demand precision, such as automotive and aerospace. By simulating how different materials will behave under stress or load, CAD helps engineers make better decisions about the design and materials, minimizing costly trial-and-error iterations.

RWhether you’re designing a simple consumer product or a complex industrial machine, CAD provides the tools needed to ensure your designs are efficient, cost-effective, and ready for the market. At X-PRO CAD, we use cutting-edge CAD technology to bring your ideas to life and guide you through every stage of product development. Contact us today to learn how we can help you bring your innovative ideas to life.

Recent Comments