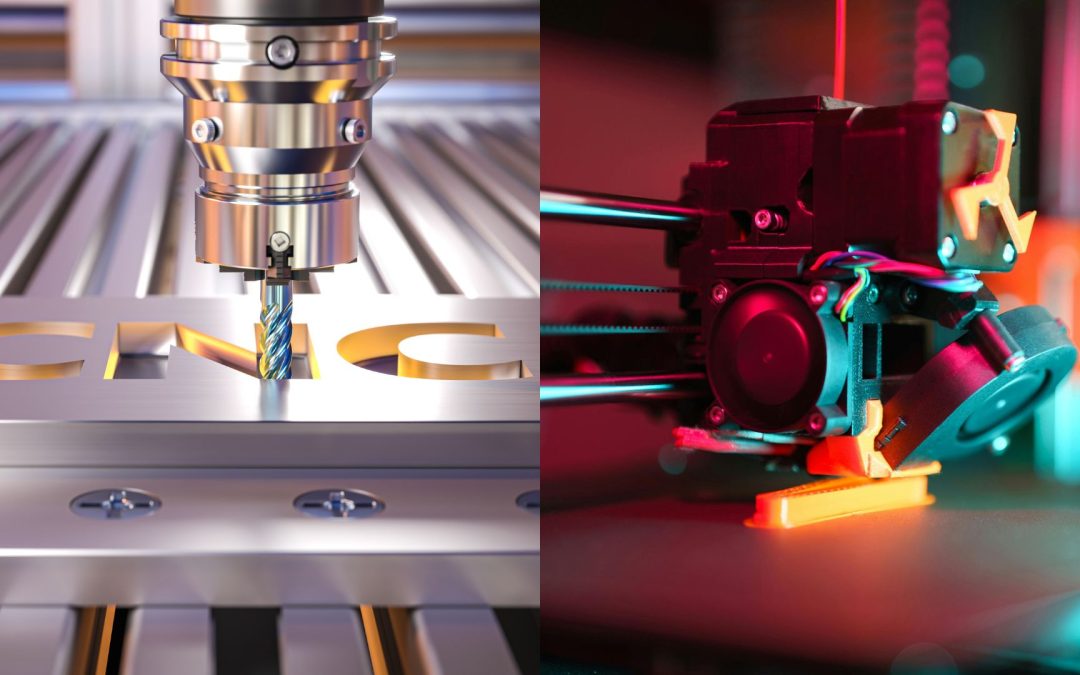

Manufacturing today gives you more choices than ever, which is why deciding between CNC machining vs 3D printing is something many people think about. CNC machining offers strength and reliable results, while 3D printing gives you more freedom for shapes that are harder to make. Your decision depends on design complexity, materials, production volume, and how quickly you need your parts. With the right knowledge, you will see where 3D printing vs CNC machining truly stand apart.

In this blog, you will gain a complete understanding of CNC machining and a full explanation of 3D printing, including the key differences between these two manufacturing methods. We will explore the manufacturing process, the materials used, precision and tolerances, speed and cost, and design complexity to help you make an informed decision. You will also learn how to choose the right method for your project and understand the benefits of using professional services to keep your product development smooth, efficient, and high-quality. Along the way, you will discover helpful insights such as CNC machining benefits and important 3D printing advantages that will guide your choice.

Understanding CNC Machining

Computer Numerical Control, also known as CNC machining, is a subtractive manufacturing method that shapes a part by removing material from a solid block. It uses machines like mills, lathes, and routers that follow computer-controlled instructions to create accurate and detailed parts. This process works with metals, plastics, and composite materials, making it a reliable choice for projects that need strength and clean finishes. One of the main CNC machining benefits is its ability to produce the same part again and again with steady quality.

Many industries use CNC machining to make mechanical parts, industrial components, and functional prototypes. It is trusted for work that needs tight measurements and durable results. This method also gives you clear control over the final shape of your part, which helps when planning budgets and comparing methods such as CNC vs 3D printing cost.

3D Printing Explained

3D printing is an additive manufacturing method that builds an object one layer at a time from a digital model. It works with plastics, resins, some metals, and composite materials, giving you many choices for different needs. One of the main 3D printing advantages is the ability to create shapes that would be hard to make with other methods. It also helps you test ideas faster because you do not need large tools or molds to begin.

Lots of people use this method to make prototypes, custom parts, and small production runs. It is also helpful for making detailed items with fine features. When looking at 3D printing vs CNC machining, 3D printing often suits designs that need curves, hollow areas, or unique patterns without raising the cost.

CNC Machining Vs. 3D Printing: Differences You Should Know

A large number of people often get confused when selecting between CNC Machining and 3D Printing. It is important that you know about the difference between them so that you will be able to make better and more informed choices.

1. Manufacturing Process

CNC Machining

CNC machining follows a subtractive method where material is carefully removed from a solid block to form the final shape. The process depends on programming, tool setup, and machine movements that cut the part with steady accuracy. It is often used when repeatable results are needed for larger batches. This approach is a key part of the CNC and 3D printing process because it focuses on shaping the part by removing material.

3D Printing

3D printing uses an additive method, building parts layer by layer from a digital model. The machine follows the design and forms the shape by adding material only where it is needed. It is useful for quick changes, custom ideas, and test pieces. This makes 3D printing and CNC manufacturing very different, as 3D printing allows fast updates without needing any tool changes or setup time.

2. Material Options

CNC Machining

CNC machining supports a wide range of metals, plastics, and composite materials, making it a strong choice for durable and functional parts. The finished pieces often have steady strength and a clean surface because they are shaped from solid material. This variety in CNC and 3D printing materials helps when you need parts made for high heat, heavy loads, or long-term use.

3D Printing

3D printing uses materials like thermoplastics, resins, and some metal powders that are designed to work well with layered building. The options are growing, but they are still more limited than CNC. Many users choose it for light parts, custom shapes, and quick tests. When comparing 3D printing and CNC materials, you can also explore metal vs. plastic 3D Printing to match strength and weight needs.

3. Precision And Tolerances

CNC Machining

CNC machining is known for tight and steady accuracy, often reaching tolerances of ±0.01 mm or better. The rigid machine setup helps each cut stay stable, which supports parts that need exact fits or smooth movement. This level of CNC and 3D printing precision makes CNC a strong choice when you need repeatable results for gears, housings, or detailed mechanical parts.

3D Printing

3D printing offers useful accuracy, but the results depend on the machine, material, and layer size. The build style can cause small shifts between layers, which affects tight measurements. Most projects still achieve dependable fits for models and light-duty parts. Understanding 3D printing and CNC tolerance helps you decide when you need layered detail or when exact measurements are more important.

4. Speed And Cost

CNC Machining

CNC machining has a higher setup cost because it needs programming, tooling, and careful machine preparation. After this setup, it becomes very fast for large batches, which helps lower the cost per part. It is a good option when you need many identical parts with steady quality. Production volume and part complexity both play a big role in CNC and 3D printing speed.

3D Printing

3D printing is more affordable for small runs because it only requires a digital file and basic material loading. It is ideal for quick prototypes or a few custom items, even if the build time for each part is slower. The cost stays fairly steady for each piece. Material use, build time, and post-processing needs all affect CNC and 3D printing costs.

5. Design Complexity

CNC Machining

CNC machining works well for parts with open shapes, flat surfaces, and round features, but it can struggle with deep internal cavities unless advanced multi axis equipment is used. Tool access often limits how creative the design can be. Designers may need to split a product into several pieces that are later joined together. This is why CNC and 3D printing design is often planned with clear tool paths in mind.

3D Printing

3D printing offers far more freedom because it builds parts layer by layer. It can create internal channels, lattice patterns, and lightweight structures that cannot be shaped with cutting tools. Designs with smooth curves, organic forms, or hidden features are much easier to produce. When needed, a hybrid approach can be used to combine printed details with machined accuracy. This reflects the real difference in 3D printing and CNC complexity.

Choosing The Right Method For Your Project

Choosing the right method is an important step because it affects how well your final part performs. Since it can be hard to compare both options, the table below gives you a clear CNC and 3D printing guide that makes choosing CNC and 3D printing easier.

| Factors to Consider | CNC Machining | 3D Printing |

|---|---|---|

| Project Goals | Better for strong parts, testing, and larger batches where repeated accuracy is needed. | Better for fast prototypes, small runs, and custom parts with unique shapes. |

| Material And Strength | Works well with metals and strong plastics when high strength is needed. | Works with many plastics and flexible materials for lighter or non-load-bearing parts. |

| Budget And Timeline | Higher setup cost but lower cost per part in larger batches. May need more time to prepare. | Lower setup cost and fast turnaround for single items or small batches. |

| Design Complexity | Best for simple and open shapes that tools can reach. | Best for complex shapes, internal channels, and detailed designs. |

| Extra Options | Can be paired with printed parts for added strength where needed. | It can be used with machined parts to reduce weight or add fine details. |

Benefits Of Using Professional Services

There are many great advantages of taking help from professional services. By reading the points below, you will learn about the benefits of using CNC and 3D printing services and how they can support your work.

- Expert guidance: You get clear advice on choosing the right method for your part. Skilled teams help you understand what works best for your goals. This saves time and prevents design mistakes early on.

- Better equipment: Professional providers use advanced machines and software that many businesses do not keep in-house. This gives you access to strong materials, detailed builds, and higher accuracy.

- Quality control: Every part goes through careful checks to make sure it meets the required measurements. This reduces rework, lowers the chance of defects, and improves the reliability of final parts.

- Fast delivery: Working with one provider avoids delays that happen when you deal with multiple vendors. This leads to quicker prototypes, smoother production, and shorter waiting times.

- Cost savings: You avoid spending money on machines, training, and maintenance. You simply pay for the parts you need, which keeps the overall cost low for both small and large projects.

- Flexible production: You can easily increase or decrease your order size based on your needs. This helps you manage new designs, test ideas, or respond to changes in your business.

- Full support: You receive professional 3D printing and CNC support through every stage, from design checks to final production. This makes the whole process easier and gives you confidence that your parts are made the right way.

Final Thoughts: Choosing CNC Or 3D Printing With Confidence

Choosing between CNC machining and 3D printing becomes much easier once you understand how each method works and what it is best suited for. Here you have learned about both processes, explored their key differences in materials, precision, speed, and design complexity, understood how to choose the right method for your project, and seen the benefits of using professional services for better results. The main idea is that neither CNC nor 3D printing is always the better choice. The best method depends on your project needs, so take time to look at your production volume, material strength, part complexity, and budget before making a decision.

We are ready to help bring your idea to life and make it simple for you. At X-PRO CAD, we turn concepts into real products by combining expert design, engineering, prototyping, and manufacturing under one roof. Whether you need precise 3D modelling, complex CAD files, fast prototyping, or full-scale production, we handle every step so you can focus on your vision. You can reach us anytime at project.inquiries@x-professionals.comor call us at (571) 583‑3710 to discuss your project details. We provide professional support, consulting, and prototyping assistance to help you bring your product to market efficiently and confidently.

Recent Comments