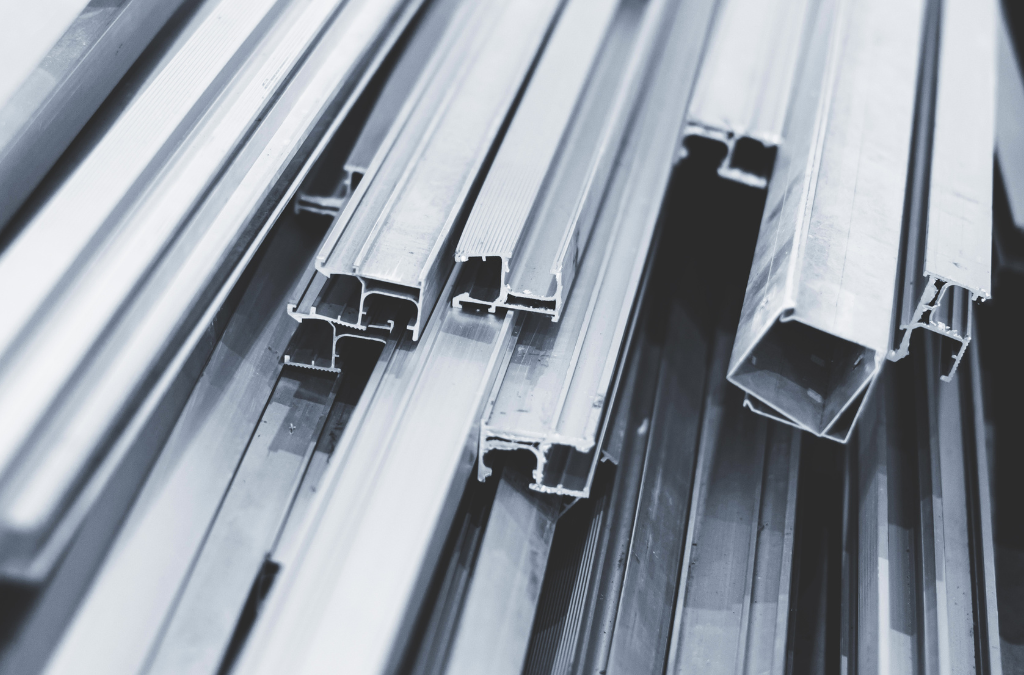

Aluminum extrusion is a pivotal process in modern manufacturing, enabling the creation of complex cross-sectional profiles with excellent strength-to-weight ratios. This technique is not only efficient but also highly versatile, lending itself to applications ranging from structural components to intricate machine parts.

The Extrusion Process

Aluminum extrusion involves forcing a heated aluminum billet through a die of the desired shape, creating elongated aluminum parts with a uniform cross-section. The process begins with the aluminum billet being heated to between 800°F and 925°F. The softened aluminum is then transferred to a press and pushed through a die. The resulting extrusions are cooled, stretched, and cut to length. This method is favored for its ability to produce complex shapes with excellent surface finish and dimensional accuracy.

Material Properties

Aluminum is widely chosen for extrusion due to its exceptional malleability and ductility, allowing for the creation of complex designs without sacrificing durability. Commonly used alloys include 6061, 6063, and 7075, each offering varying benefits in terms of strength, corrosion resistance, and finishing characteristics.

Applications in Industries

The automotive industry utilizes aluminum extrusions to reduce vehicle weight and improve fuel efficiency while maintaining safety standards. In construction, aluminum extrusions are used in framing, railings, and window frames due to their durability and resistance to weathering. Aerospace applications include airframes and fuselage structures, where the material’s strength and lightness are crucial.

Advancements in Aluminum Extrusion

Recent advancements include the use of sophisticated simulation software to predict the flow of aluminum through dies, enhancing precision in manufacturing. Additionally, there is an increasing trend towards using recycled aluminum, reducing the environmental impact associated with extraction and processing.

Understanding aluminum extrusion is crucial for leveraging its full potential in manufacturing processes. Its combination of efficiency, versatility, and sustainability makes it a cornerstone of modern industrial design.

Explore the possibilities of aluminum extrusion in your projects. Contact us at X-Pro CAD Consulting for expert guidance and tailored solutions. .

Recent Comments